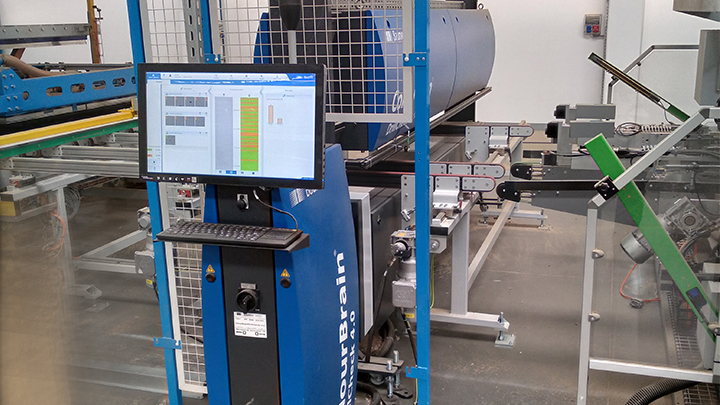

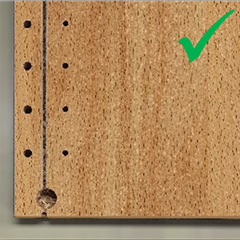

The inspection system ColourBrain® DrillCheck 4.0 is the technological leader in the inspection of drill hole patterns for furniture components. Deviations in the pattern and grooves are reliably detected, visualized and alarmed. The inspection can be carried out on one or both sides of the component - without adjustments to the decor and structure and completely independent of height. The compact design is optimized for fast setup and allows easy integration into your existing production line.

Fixed preset, calibrated multi-sensors and predefined inspection parameters on delivery ensure easy commissioning according to the „plug-and-work“ principle. Thanks to the ready-to-install solution with laser scanning, the ColourBrain® DrillCheck 4.0 inspects your entire product range in just a few steps and without any adjustment to component thickness, surface structure or decor.

Your benefits at a glance:- With the smart 3D technology, drill hole patterns and grooves are reliably checked. Deviations are detected, analyzed and reported.

- The inspection is independent of the decor, structure and thickness of the components.

- Fast integration and commissioning according to the plug-and-work“ principle.

- Product change through simple Teach-In or the transfer of existing patterns.

- Improvement of the quality standard through immediate inspection after drilling.

- The system is used for process monitoring, both in series and batch 1 production.